Umatshini wokuwelda welaser ophathwa ngesandla

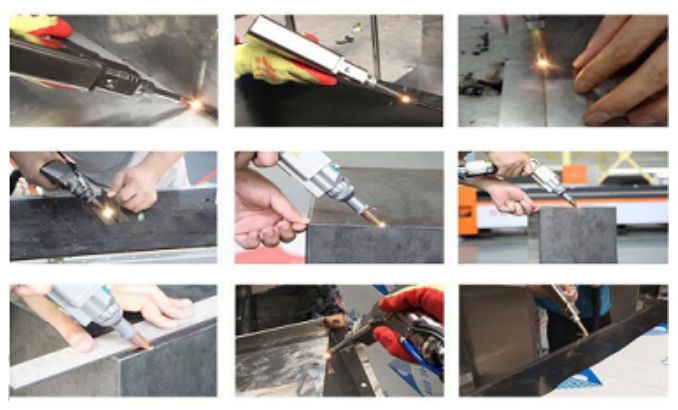

I-Laser welding kukusebenzisa i-high-energy laser pulses ukwenza ukufudumeza kwendawo kwindawo encinci kunye ne-high-energy laser pulses.Amandla emitha yelaser yenziwa ngokunyibilika kwezinto ngokusasazwa kwangaphakathi kwesixhobo sesikhokelo se-thermal ukwenza ichibi elithile lokunyibilika.Luhlobo olutsha lwendlela yokuwelda.Ijolise ikakhulu kwi-welding yezinto ezincinci ezinodonga kunye neengxenye ezichanekileyo.Iyakwazi ukuqaphela i-welding point, i-welding yokudibanisa, i-welding edibeneyo, i-welding yokutywina, njl.I-deformation encinci, isantya se-welding ekhawulezayo, i-flat welding seams kunye ne-aesthetics, akukho unyango emva kwe-welding okanye ukusetyenzwa nje, umgangatho we-weld ophezulu, akukho pores, ulawulo oluchanekileyo, iindawo ezincinci zokukhanya, ukuchaneka kokubeka okuphezulu, kunye nokulula ukufezekisa ukuzenzekelayo.

Enyanisweni, kuya kubakho ukuthengisa okulungileyo kakhulu kolu hlobo lwezixhobo zokutshisa, ezinomsebenzi omkhulu kunye neempawu zayo, kwaye ezi mpawu zibonakaliswa ngokubanzi kule miba ilandelayo.

1. Ukusebenza kwe-welding kuphezulu.Uninzi lwezixhobo zokuwelda zemveli zinokuzisa iziphumo ezingcono ekusetyenzisweni kokwenyani, kodwa ngenxa yokuba ukusebenza kakuhle kucotha xa ufaka isicelo, izicelo ezifunyenwe kancinci kancinci.Umatshini we-laser welding ayifani.Kuya kufuneka uyazi ukuba ukusebenza kakuhle komsebenzi wokuwelda okuziswe lolu hlobo lwezixhobo kuphezulu kakhulu.Kubalulekile ukugcina iimfuno ezithile ezicocekileyo ngexesha lenkqubo yonke ye-welding.

2. Isiphumo se-Welding sicacile.Kwezinye i-welding workpieces ezinzima, kuyimfuneko ukusebenzisa izixhobo zokuwelda eziphambili.Ngenxa yokuba izixhobo eziphambili zinokufikelela kwiziphumo ezingcono ze-welding ngexesha lenkqubo yesicelo, kwaye ayinayo nayiphi na impembelelo ekubonakaleni kwe-workpiece.Oomatshini bokuwelda beLaser zizixhobo ezinjalo, amaxesha amaninzi xa bedibana nezixhobo zokusebenza ezinobunzima obungakumbi bokuwelda, abantu bakhetha ukusebenzisa olu hlobo lwesixhobo.

| Umzekelo | EC-1500/2000 |

| Amandla eLaser | 1500W/2000W |

| Ubude beLaser | 1080nm 1064nm±5nm |

| Imo yeLaser | Imowudi enye |

| Ukuphumelela kokuguqulwa kweefoto zombane | 30% |

| Uhlobo lomsebenzi | ngokuqhubekayo |

| Ubude beFayibha | 10m |

| Uhlobo lokupholisa | Ukupholisa amanzi |

| Imodeli epholileyo | 1500W / 2000W |

| Ukupholisa ubushushu bamanzi | 20-25℃ |

| Ukunikezwa Amandla | AC220 AC380±10%,50/60Hz |

| Ubushushu bokusebenza | 10 ~ 35℃ |

| Ukufuma kwendawo yokusebenza | ≤95% |

| Uluhlu lohlengahlengiso lwamandla | 5-95% |

| Ukungazinzi kwamandla | ≤2% |

| Ugqithiso lwedayimitha yefiber core | 25um-50um |

Impahla yococeko kwindawo yokuhlambela yangasese, ukuwelda ukuwelda kwemibhobho yamanzi, uqhagamshelo lwe-transformer, iindlela ezintathu, iivalvu zesango, kunye neshawari.

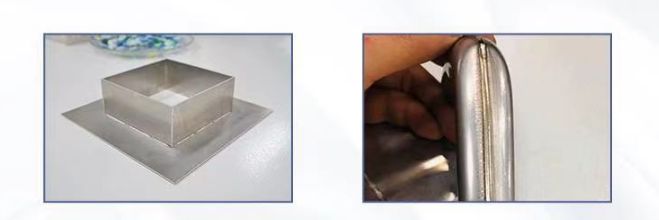

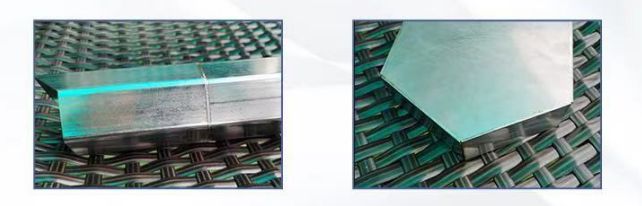

Imboni yokuvelisa iiglasi: i-welding ephezulu-echanekileyo ye-welding yeepleyiti zensimbi ezingenasici, i-aluminium alloy kunye nezinye izinto ezifana nesakhiwo, umda kunye nezinye iindawo zesakhelo.

Umzi-mveliso we-Hardware: i-centrifugal impeller, i-teapot, umqheba womnyango, njl., ukuwelda i-welding ye-hardware ye-stamping parts enzima, iinxalenye zentsimbi.

Ukwenziwa kweemoto: iipads ze-injini yemoto, ii-hydraulic presses ezinde ze-tingle welding, i-car spark plug welding welding, i-welding element welding welding, njl.

Umzi-mveliso wezixhobo zonyango: izixhobo zonyango, oomatshini bonyango bentsimbi yokutywina iinxalenye zokutywina zentsimbi, kunye newelding yamacandelo.

Umzi-mveliso we-elektroniki: ukutywina ukuwelda kwi-welding ephakathi, ukuwelda izihlanganisi zezihlanganisi, kunye nokuwelda amaqokobhe eplastiki afana neeselfowuni kunye neMP3 kunye namalungu.I-welding yombane ye-welding ye-motor shell kunye nomgca odibeneyo, i-optical fiber adapter connector.

hardware Family, izinto zasekhitshini, lokuhlambela ware sanitary, steel stainless ipleyiti umnyango ukutsala izandla, amacandelo elektroniki, izivamvo, iiwotshi, oomatshini echanekileyo, unxibelelwano, ubugcisa kunye nezinye iinkalo, oomatshini isithuthi hydraulic kunye nezinye ukumelana eliphezulu-uxinzelelo endle Welding ezi.

Umatshini wonke ubandakanya ezi zinto zilandelayo: umatshini wokuwelda, i-wire feeder, imitha yegesi ye-argon, iiglasi, izixhobo ezine-hexagonal, iiglavu, umbhobho oxhasayo, ilensi yokukhusela.

| Igama lenxalenye | Ubungakanani (iseti) | Igama lebrand |

| Isixhobo seLaser | 1 |

|

| Intloko yeLaser | 1 |

|

| Ubushushu obuphindwe kabini bokulawula i-chiller | 1 |

|

| Iqhosha lokutshintsha amandla | 4 | Yijia |

| Ivalve ye-electromagnetic | 1 | Yadeke |

| Umnxibelelanisi we-AC | 2 | Zhengtai |

| Ukutshintsha master | 1 | Delixi |

Iwaranti iyonke yomatshini wokuwelda unyaka omnye ngaphandle kwekhabhinethi.Iilensi zeLaser, iilensi zetotshi zokuwelda, kunye nemilomo yethusi zizinto ezisengozini kwaye azigqunywanga kwiwaranti.